When it comes to dental crowns, understanding the manufacturing process is crucial in appreciating their durability and functionality. Let's delve into the intricate steps involved in crafting these essential dental prosthetics.

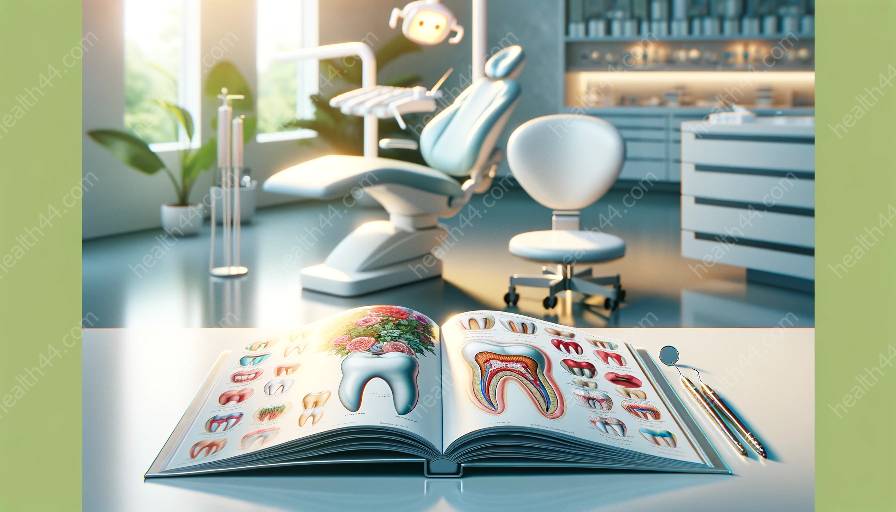

Understanding Tooth Anatomy

Before delving into the manufacturing process of dental crowns, it's important to have a basic understanding of tooth anatomy. The tooth's structure includes the enamel, dentin, pulp, and cementum, all of which play a crucial role in supporting and protecting the tooth.

The Role of Crowns in Dentistry

Dental crowns, also known as caps, are designed to cover a damaged or weak tooth, restoring its shape, size, strength, and appearance. Crowns are essential in protecting and preserving the functionality of previously damaged teeth.

The Manufacturing Process

The manufacturing process of dental crowns involves several intricate steps that combine artistry and precision engineering. Here's an overview of the meticulous process:

- Patient Assessment and Preparation: The process begins with a comprehensive assessment of the patient's dental health, including X-rays and impressions to determine the exact specifications for the crown.

- Tooth Preparation: Before a crown can be manufactured, the tooth needs to be prepared. This involves removing any decay and shaping the tooth to provide a solid base for the crown.

- Impression Taking: A precise impression of the prepared tooth is taken using advanced materials such as dental putty or digital scanning technology. This ensures that the crown will fit seamlessly into the patient's mouth.

- Crown Design and Fabrication: The impression is used to create a precise model of the patient's tooth, which serves as the basis for designing the crown. Advanced CAD/CAM technology may be employed to design and fabricate the crown with unparalleled accuracy and detail.

- Material Selection: Dental crowns can be manufactured using various materials, including porcelain, ceramic, metal alloys, or a combination of these materials. The choice of material depends on factors such as durability, aesthetics, and the patient's specific requirements.

- Crafting the Crown: The chosen material is carefully shaped and crafted to create a custom-fit crown that matches the natural contours of the patient's tooth. Artisanal skill and meticulous attention to detail are essential in this step.

- Bonding and Finishing: Once the crown is manufactured, it is carefully bonded to the prepared tooth using dental cement. Any final adjustments are made to ensure a perfect fit and comfortable bite. The crown is polished to achieve a natural appearance that blends seamlessly with the patient's existing teeth.

- Patient Satisfaction: The patient's satisfaction and comfort with the newly fitted crown are of utmost importance. Any necessary adjustments or modifications are made to ensure that the crown meets all functional and aesthetic requirements.

Materials Used in Crown Manufacturing

The choice of material for manufacturing dental crowns depends on various factors such as durability, aesthetics, and the specific requirements of the patient. Here are the common materials used:

- Porcelain: Porcelain crowns provide excellent aesthetics and are a popular choice for front teeth due to their natural appearance.

- Ceramic: Ceramic crowns are known for their durability and natural-looking translucency, making them suitable for both front and back teeth.

- Metal Alloys: Metal crowns, such as those made of gold or platinum, offer exceptional durability and strength, making them ideal for back teeth that undergo significant chewing forces.

- All-Ceramic or Porcelain-Fused-to-Metal (PFM) Crowns: These crowns combine the aesthetics of porcelain with the strength of metal, making them a versatile option for various dental restoration needs.

Conclusion

Manufacturing dental crowns is a meticulously detailed process that combines advanced technology, precise craftsmanship, and a deep understanding of tooth anatomy. By understanding the intricacies of crown production and the materials used, patients can gain a deeper appreciation for the value and functionality of these essential dental prosthetics.