The advent of 3D printing technology has significantly transformed the traditional methods of denture production, revolutionizing the dental industry. This topic cluster aims to explore the impact of 3D printing technology on denture manufacturing, its compatibility with dentures, and its influence on tooth anatomy.

Understanding Dentures

Dentures are artificial replacements for missing teeth and the surrounding tissues. They are custom-made to fit the unique oral structure of each patient and contribute to restoring the functionality and aesthetics of the mouth.

Evolution of Denture Production

Traditionally, the fabrication of dentures involved a labor-intensive and time-consuming process. It required multiple appointments, extensive manual labor, and often resulted in inconsistencies in the final product. However, the introduction of 3D printing has revolutionized the approach to denture production, offering a more efficient and precise method.

Advantages of 3D Printing Technology

3D printing technology enables the creation of dentures through additive manufacturing, utilizing digital models to produce highly accurate and customized dental prosthetics. This method offers several advantages:

- Precision and Customization: 3D printing allows for the creation of individualized dentures that perfectly align with the patient's oral anatomy, resulting in improved comfort and functionality.

- Time-Efficiency: With 3D printing, denture production requires fewer steps and reduces the overall processing time, allowing patients to receive their prosthetics more quickly.

- Cost-Effectiveness: The streamlined production process and reduced material wastage contribute to cost savings for both dental practitioners and patients.

- Enhanced Aesthetics: 3D printing technology enables the incorporation of intricate details and natural-looking tooth anatomy, enhancing the overall aesthetics of the dentures.

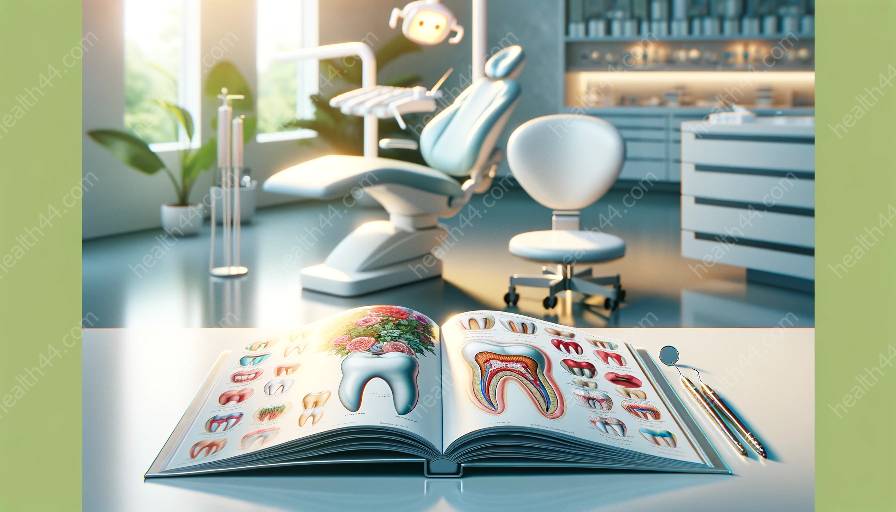

Compatibility with Tooth Anatomy

3D printing technology has significantly enhanced the compatibility of dentures with tooth anatomy. By utilizing advanced digital scanning and modeling, dental professionals can capture precise measurements of the oral cavity and design dentures that closely mimic the natural alignment and contours of the patient's teeth and gums.

This level of compatibility ensures a more secure fit, improved functionality, and a natural appearance, addressing the limitations of traditional denture production methods.

Impact on Tooth Anatomy

3D printing technology has revolutionized denture production by directly impacting tooth anatomy. Through precise digital design and layer-by-layer fabrication, 3D-printed dentures can closely replicate the intricate structures and nuances of natural teeth.

This level of detail not only enhances the aesthetics of the dentures but also contributes to improved chewing efficiency, speech clarity, and overall oral health.

Future Implications

The continuous advancements in 3D printing technology are poised to further revolutionize denture production. Future innovations may include the integration of biocompatible materials, enhanced color matching, and the development of more advanced scanning and modeling techniques.

Ultimately, 3D printing technology holds the potential to elevate the standard of care in prosthodontics, offering patients highly personalized, functional, and aesthetically pleasing dentures that seamlessly integrate with their natural tooth anatomy.